American Made Distilling Equipment

Since 1952, we have led the way in American craftsmanship and quality with our mechanical expertise, fabrication capabilities, and legendary no-pressure customer service. Now, Crawford Brewing and Distilling Equipment wants to help you design, build, and install your dream craft distillery. Whether you have an existing brewery or are starting from scratch, we have a solution for you. This page may help answer some of your questions if you have been considering opening a distillery.

Want To Open A Craft Distillery?

Our Commitment to You: White Glove Turnkey Service Without an Upcharge

Crawford Brewing and Distilling Equipment is unique because while our competition may deliver tanks, we deliver peace of mind – and you don’t have to pay extra for it. Through volume, we work with our supplier-partners to achieve an economy of scale. If we sell you something that we bought from someone else, we sell it to you for the same price you would have paid if you bought it from them directly. So, you could personally work with fifteen different suppliers, managing shipping, sizing, integration, payments, and lead times yourself, or you can have us manage it for you and rest assured that everything will be in the right place at the right time, and work properly. You’ll save time, and be able to focus on your business while we tackle your project.

Q: Is there a financial advantage to adding a distillery to an existing brewery?

A: Absolutely. You already own a brewhouse, fermenters, and probably a boiler. If you have a cold liquor tank, that’ll save you even more. We have pot stills in 7, 10, and 15bbl volumes designed to match the size of your brewery. You can make whiskey, gin, rum, vodka, and liqueurs by adding a pot still, proofing tank, reverse osmosis water system and cold liquor tank if you don’t have one. Some other accessories such as a special pump, hoses, and fittings will be needed as well. We have everything you’ll need and a consultation with one of our designers can help bring your project into focus.

There’s also lots of creative opportunities for crossover when you have an existing brewery. If you are barrel ageing spirits, think of all the fun you can have with used whiskey, rum, and gin barrels. Gin barrel aged IPA anyone? Whiskey barrel aged Russian Imperial Stout? How about canned cocktails? Mix up a batch of gin and tonic in your brite or unitank, carbonate it, and can it off. You can also make hard seltzer from vodka, water, and fruit or food flavoring. The possibilities for new markets and customers are endless.

Q: Can you give me a basic summary of how I would make distilled spirits in my brewery?

A: Whiskey and bourbon are extremely popular and you can start making these spirits yourself, maximizing margin and drawing additional customers to your business. All bourbon is whiskey, but not all whiskey is bourbon. Did we lose ya? If you have an existing brewery it is very simple to make malt whiskey, also called “single malt”. Basically, it’s distilled unhopped beer that can be sold as an unaged white whiskey or as a barrel aged product. Malt whiskey is some of the highest quality, greatest whiskey on the market. Do not consider this a step down from bourbon – it’s just different. We would encourage you to go buy some craft malt whiskey and try it.

If you want to make bourbon, it will require additional equipment such as a mash cooker and special fermenters. The “beer” that becomes bourbon doesn’t have the grain removed from the wort before fermentation. Grains are milled finely, mashed in a cooker without a lautering screen, and the whole mash is cooled and fermented. We have all of the equipment necessary to make bourbon as well. If you go this route, it opens up a lot more opportunity in the world of vodka and gin and we’ll cover that in a moment.

If you have an existing brewery you can also make rum from a “sugar wash”. You will mix up a sugar solution (usually cane, beet, or corn sugar) in your mash tun or brew kettle and ferment it in your beer fermenters. Once distilled, this can be sold as an unaged white rum or barrel aged. This also makes an excellent base for liqueurs and cordials.

There are a couple typical ways craft distillers make vodka and gin. The most cost-effective method is to purchase grain neutral spirits, referred to as GNS. It’s nearly pure ethanol. When added to your pot still with some water, it can be distilled in a single pass into vodka, or gin if you send the vapor through a “gin basket” filled with the botanicals of your choice. To be vodka, the spirit must come off the still at a higher proof than whiskey. This can be achieved in a whiskey still in one pass when starting with GNS. If you wish to make vodka and gin from scratch (wheat or other starch source), you will need the same equipment for bourbon and also some additional distillation plates in your column. We can explain more in depth when you contact us.

The bottom line is that malt whiskey and rum, and gin and vodka from GNS, can be made with the least amount of equipment. For bourbon you’ll need a few more pieces, and for vodka and gin from scratch, slightly more.

Q: I don’t have a brewery, and I wasn’t planning on one. Can you help me build a distillery from the ground up?

A: Just as with brewing, we are a turnkey distilling equipment provider. We can help you with absolutely every facet of your project from space planning and architecture to installation and training. We even offer financing. Give us a call or email to see how we can help you make your project an easy and fun experience.

Q: Buying American made equipment is very important to me. Where is your equipment fabricated?

A: It’s extremely important to us too and we consider it a cornerstone value in our company. Everything we make is made in the USA. We fabricate all of our stainless steel products in Rock Island, IL. Copper stills are fabricated by our partner plant in Oregon. You are welcome to stop by either facility and see why we say our craftsmanship is the best in the industry, and worlds beyond tanks made in China. We also have a brewery in Bettendorf, IA and we’d love to show you our equipment in action.

Here are some definitions of words used to discuss distilling and distilling equipment:

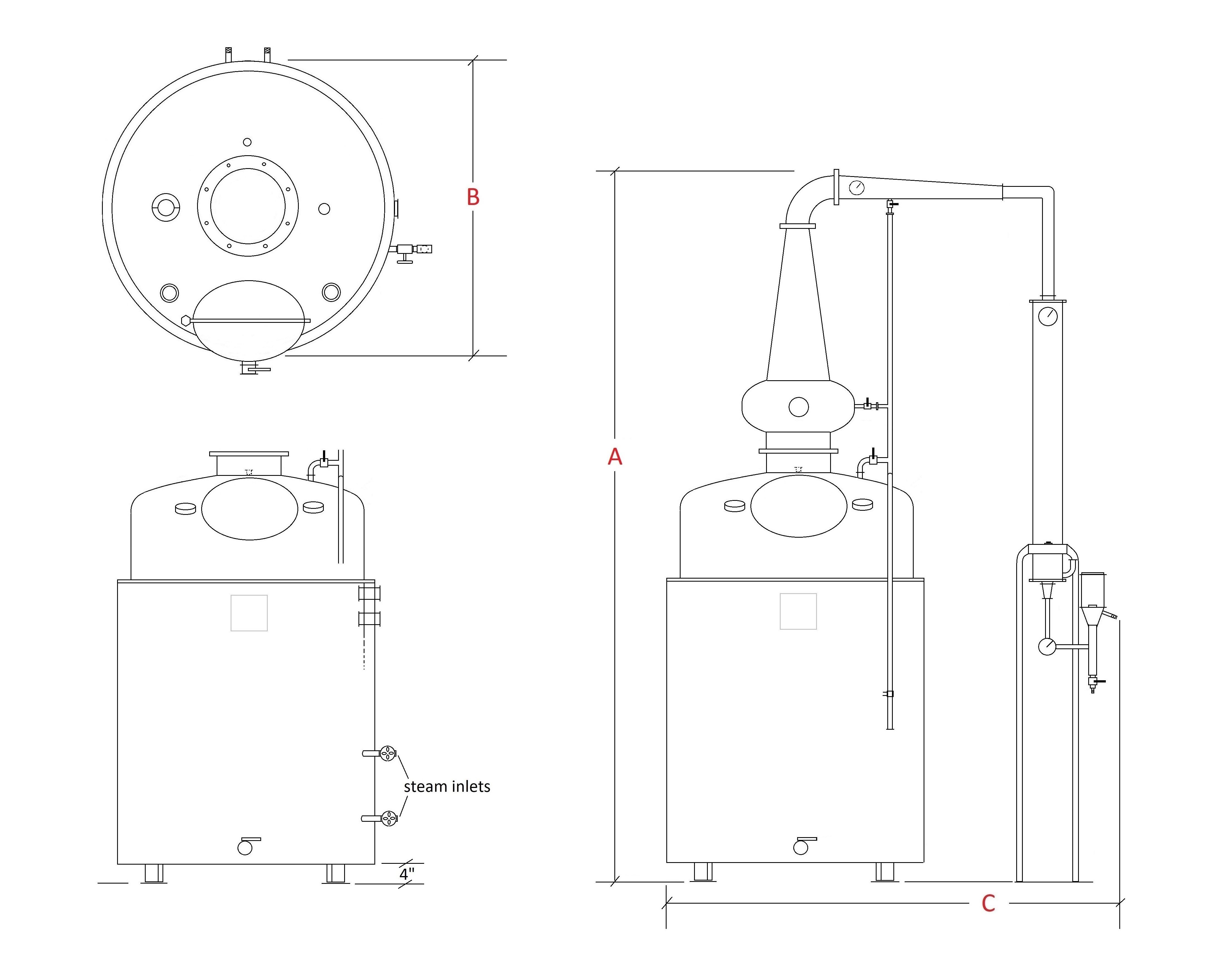

Pot – The pot is a steam jacketed and agitated kettle similar to a mash tun but without a lautering screen. Think of a brew kettle with an XP agitator. Pots are available in 7bbl (217 gallons), 10bbl (310 gallons), and 15 bbl (465 gallons) volumes though other sizes are available.

Helmet – The helmet goes on top of the pot and is the first thing vapor travels through before entering the column. The purpose of the helmet is to provide some air-cooled mass that flares outward. As the vapor rises into the helmet, some of it will condense and drip back down into the pot to be distilled again. This is called “reflux” and raises the proof of the vapor which does eventually make it through. In a way, this is the “first distillation” out of many that will happen as the vapor travels through the still and column(s).

Lyne Arm – The lyne arm sits on top of the helmet in side mounted column stills. It is comprised of a 90-degree elbow and long arm which reduces in diameter to eventually meet up with the process piping.

Column & Plates – Columns can be placed directly on top of the pot instead of a helmet, or they can be placed next to the pot and connected by process piping. In some cases, there will be two columns next to the pot and the vapor travels from one to the next and eventually to a condenser. Inside the column are plates. The purpose of a plate is to collect a small amount of water that the vapor must rise and bubble through in order to get to the next plate. This action creates reflux, and each time the vapor makes it to the space above each plate, it is higher in proof. Plates can be deactivated by opening a drain valve. When open, the plate cannot hold any liquid and the vapor will pass through it like it’s not even there. For this reason, the user must purchase a still with the minimum number of plates they need to produce the spirits they desire. For example, making vodka from grains requires more plates than whiskey because the end product is supposed to come off the still at a higher proof. Whiskey can be run on a still with more plates than necessary because the distiller can deactivate the plates they don’t want to use.

Dephlegmator – Referred to as the “dephleg”, pronounced [Dee-Flag], this device sits on top of the column and is a tube in shell heat exchanger using cool water originating from a cold liquor tank. Vapor travels through the tubes which are surrounded by water and the distiller controls the water temperature very accurately in order to control the rate and temperature of reflux within the column, and therefore the temperature of vapor allowed to pass through the dephleg and on to the condenser or the next column. Compounds such as acetone and methanol have lower boiling points than ethanol and the distiller uses the dephleg set temperature to separate these vapors during the distillation process so the distillate compounds can be separated as well. The separations are referred to as “cuts”. Without this device, the distiller would have a more wasteful process where the vapors have longer periods of intermingling, and more of the desirable distillate would be mixed with the undesirable. On stills that have two side-mounted columns, there are two dephlegmators, one on top of each column and they are set at different temperatures. The cooling water supply is the same temperature, but the distiller throttles it with a self-modulating thermostatic valve to control to level of cooling against the hot vapor travelling through them.

Condenser – This is a simple tube in shell heat exchanger that is designed to take the vapor that passed through all of the still apparatus and phase change it to a liquid for collection. The water to operate this can come from the same source as the dephlegmator(s) or from a municipal source. On a pot still, the temperature of this water is less important than the water used in the dephlegmator(s).

Gin Basket – This is a small stainless steel chamber that holds botanical ingredients for the production of gin. It is positioned after the column(s) and before the condenser. The strong flavors and aromas given off by these ingredients are not always easy to clean out of a still, and for this reason, customers will have to choose between a dedicated still for gin making, a separate condenser and spirit safe for gin making connected by process piping, or plan to do long batch runs of gin and rigorously clean their still afterwards before producing another non-gin spirit.

Spirit Safe – A spirit safe is a three chambered receiving tank for collecting distillate. As the different vapors come off the still over the course of the batch, the distiller will route them into each of the three chambers. The “foreshots” and “heads” come off first and are collected in the smaller first chamber. These are generally discarded due to their high acetone and methanol content, or used as sanitizer, cleaner or fuel. The distiller makes the cuts, or transitions from one collecting chamber to another, by taking into account the temperature of the boil pot or column, and the proof, flavor and aroma of the distillate. The “hearts” are desirable ethanol, and they will come off next and comprise the vast majority of the collection. They run into the large middle chamber for later transfer to a proofing tank. Towards the end of the hearts collection, the proof will drop as the temperature on the dephleg is allowed to rise, and more and more undesirable compounds will become included into the ethanol. These compounds are consumable by humans, but have an increasingly undesirable flavor and aroma. Some of these compounds are allowed into the hearts collection and this small inclusion can be a trademark flavor and aroma imparted by the distiller on purpose. At some point, the distiller will decide that these compounds have reached an undesirable point and at the same time the ethanol distillate is at an unacceptably low proof. A final cut will be made and the distillate will run into the smaller third chamber in the spirit safe. This distillate still contains valuable ethanol and will most likely be added back to the pot before the next batch is started. The undesirable compounds will be distilled out in the same manner and some of the ethanol recovered.

Parrot – The parrot is a small chamber with sight glass positioned after the condenser that the distillate must pass through on its way to the spirit safe. A hydrometer is floated in the chamber and viewed through the sight glass to determine the proof of the distillate coming off the still in real time.

Proofing Tank – This is a receiving tank designed to hold several batches of hearts before they enter the next phase of the process depending on what type of spirit is being produced. In the case of barrel aged spirits, the distillate may need to be diluted with RO water before it enters the barrels. This is done by weight and the tank includes load cells for this purpose. This same tank can be used when finished barrel aged spirits are combined in it, and proofed down again for bottling. The tank can feed a bottling line as well. More than one of these may be needed in a distillery to manage the different streams and schedules, and a dedicated one may be desired for gin.